SETTING THE TIME – FOR ALL CLOCKS – (moving the hands)

METHOD ONE

- TURN OFF THE CHIMES

- Move ONLY THE MINUTE HAND clockwise (FORWARD) until the hour and minute hand are at the correct time. (See Figure 5).

- DO NOT MOVE THE HOUR HAND WHEN SETTING THE TIME. The hour hand will move automatically when the minute hand is moved.

- If after setting the clock on time, it does not chime properly, permit it to operate a few hours to self-correct.

METHOD TWO:

- KEEP CHIMES TURNED ON.

Move the minute hand CLOCKWISE to the next Quarter-hour, and you will hear a light “click,” and the clock will chime. After the clock completes that chime, proceed CLOCKWISE to the next quarter hour, and after the chime completes, you may go to the next quarter hour.

Wait for the clock to chime as the minute hand passes each quarter hour.

- WINDING YOUR CLOCK

Fully insert the winding key into the holes located in the dial face. For Clocks with Hermle movements, turn the key clockwise until the spring becomes tight and will not turn further. Kieninger movements are wound counter-clockwise. Do not force. This will power the clock for a full week. Chime speed will slow when the spring tension is reduced at the end of a week. Your clock should be fully wound on delivery.

4:00 Winding Hole – This powers the Westminster Melody.

6:00 Winding Hole – This one powers the time

8:00 Winding Hole – This one powers the hour count.

*If your chimes are turned off, the 4:00 and 8:00 positions need not be wound.

-

-

CHIME SELECTION

-

Move the chime lever UP to chime or DOWN to silence. Selecting the chime melody is accomplished by moving a lever on or next to the clock dial or in the back of the clock. If the dial states “WESTM-SILENT” or “CHIME-SILENT,” your clock has only the Westminster chime. For most clocks, UP is CHIME ON, and down is CHIME OFF.

The chime lever identifies the melody choices if your clock has a triple chime movement.

Never change the selection while the clock is chiming or positioned near the release points near a Quarter-hour.

It is safe to move the chime selection lever without damaging the movement. If the minute hand is pointing diagonally in any direction, it is then all right to move the chime on/off lever.

-

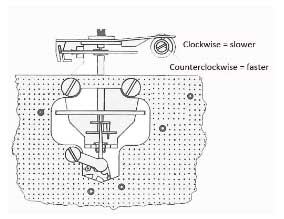

Hermle clock speed adjustment REGULATING THE SPEED OF THE CLOCK

Hermle movements have an adjustment screw at the very top right and are turned with a jeweler’s flathead screwdriver.

Make only a small adjustment each time (about 1/16 of a turn).

Clockwise = slower

Counterclockwise = faster

To make the clock go slower or faster, turn the regulating screw that is shown in the upper right of the picture backward (counterclockwise)

If your clock is FAST, To make the clock go slower: turn the screw clockwise.

If your clock has a Kieninger movement, move the lever up or down to adjust the clock speed.

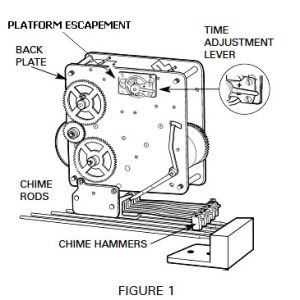

Figure 1. displays the most common Kieninger mantel clock movement. This model uses a unique platform escapement, which regulates the spring tension so the clock will keep the proper time. There is a lever that points to the right that may be moved up or down to change the tension on the wheel to change the speed – fast to slow. A clear plastic dust cover covers the escapement, but the control arm is still accessible. Move this arm (the Timer Adjustment Lever) ever so gently as it is sensitive. A very small change in the position of the lever will dramatically change the clock’s speed.

If the clock is fully wound and the wheel on the platform escapement is not moving, carefully take off the clear plastic cover and very gently, give the wheel a slight touch on the top just enough to start it moving. It should continue moving. If not, the platform escapement may need replacing.

- CLOCK DOES NOT STRIKE THE CORRECT HOUR If, after several hours of operation, your clock does not strike the correct hour, grasp the HOUR HAND ONLY and move it forward or backward to line up with the correct hour on the dial indicated by the number of times the hour strikes. Rotating this hand independently will not damage the clock.

- CARE AND MAINTENANCE Your clock requires little care and maintenance. Listed below are steps you can take to maintain the exceptional quality of your Hermle clock.

- Wind your clock every seven days.

- Wax and polish your clock cabinet as frequently as you do your other furniture. Use a nonsilicone liquid or paste wax.

- When cleaning glass, use a non-ammonia glass cleaner. Never spray the cleaner directly on the clock.

- Avoid exposing the clock to direct sunlight or high-intensity lighting, which may fade the finish. Protect from extreme temperatures and humidity changes, which may cause the wood to split or crack.

• SETTING UP YOUR CLOCK

Located in the shipping carton with the clock will be a key to wind the clock. If provided on your model, the shipping carton may also include a pendulum and finial that are separately packed. Please keep all of the original packaging material.

TIME ADJUSTMENT

Changing the speed of timekeeping is accomplished by moving the time adjustment lever on a part called the “Platform Escapement”. (See figure 1). To slow the clock, move the lever down towards the “-” (minus). To speed the clock up, move the lever up towards the “+” (plus). A very small change will make a large difference in the time (fast or slow) on the clock. Always keep the plastic cover on and avoid touching the small spinning gear inside. This part is very fragile.

CHIME SELECTION

The chime melody is selected by moving a lever on or next to the clock dial. Some models play only the Westminster chime, while others give you a selection of three melodies.

If the dial states “WESTM-SILENT” or “STRIKE-SILENT”, your clock has only the Westminster chime. If your clock has a triple chime movement, the chime lever identifies the melody choices.

Never change the selection while the clock is chiming or positioned near the release points. See figure 9 for when it is safe to move the chime selection lever without damaging the movement.

CARE AND MAINTENANCE

- Your clock requires little care and maintenance. Listed below are steps you can take to maintain the exceptional quality of your Howard Miller clock.

- Wind your clock every seven days.

- Wax and polish your clock cabinet as frequently as you do your other furniture. Use a non-silicone liquid or paste wax.

- When cleaning glass, use a non-ammonia glass cleaner. Never spray the cleaner directly on the clock.

- For clocks with hanging weights, check the weights occasionally to ensure that they are still tightly assembled.

- Avoid exposing the clock to direct sunlight or high intensity lighting which may fade the finish. Protect from extreme temperatures and humidity changes, which may cause the wood to split or crack.

- It is recommended that your clock movement be oiled every two years from the date of purchase and thoroughly cleaned every five to ten years, depending on climatic conditions. Extremely dry, humid or salty air, heat or cold may necessitate more frequent servicing. Howard Miller does not recommend that you service the clock movement yourself. Contact a Service Center.

TROUBLESHOOTING

Ensure that all instructions provided with your Howard Miller product have been carefully followed. These instructions will provide detailed information to answer most questions. Contact the Howard Miller web site (www.howardmiller.com) for a list of frequently asked questions that may conveniently resolve your problem or answer your questions.

MOVE CHIME SELECTION LEVER ONLY WHEN MINUTE HAND IS IN SAFE TIME AREA

CLOCK DOES NOT CHIME AT PROPER TIME

If the clock chimes more than one minute before or after the proper time, the minute hand should be removed and adjusted.

When performing this operation be careful not to scratch the hand nut, hand or dial.

- When the clock starts to chime, stop the pendulum and record the time.

- Using pliers, carefully remove the small nut that holds the minute hand in place by turning the nut counterclockwise while at the same time hold the minute hand with your fingers near the small nut.

3. Remove the hand from the hand shaft by grasping it with your fingers at the point where it attaches to the shaft. Pull the hand straight off. This hand is not screwed on and should come off easily. The minute hand has a small raised area on the back side directly around MINUTE HAND the shaft hole, this is the hand bushing. Using pliers, grip the bushing firmly by its sides so that it cannot slip in the pliers. With your other hand, turn the clock hand forward or backward the distance necessary to chime at the correct time.

HAND BUSHING

- Re-attach the hand to the shaft and turn the hand nut finger tight. Make sure the hand points to the correct location that you recorded in Step 1 plus any corrections you made in step 3. If the hand does not point to the correct mark, repeat steps 2 and 3.

- Snug up the hand nut with the pliers. Do not over-tighten.

- Start pendulum.

- Re-set the time by moving ONLY THE MINUTE HAND backwards as described in the set-up operation.

EXAMPLE: Clock chimes at 1:10 but should chime at 1:15. Step 1: When clock chimes at 1:10 stop the pendulum and record the time of 1:10. Step 2: Carefully remove the small nut. Step 3: Remove the minute hand. Grip the bushing by its sides and turn the hand forward 5 minutes. Step 4: Reattach the hand so it points to 1:15. Attach the hand nut finger tight. Step:5 Snug up the hand nut. Step 6: Start pendulum. Step 7: Reset clock to current time.

CLOCK DOES NOT STRIKE THE CORRECT HOUR

If after several hours of operation your keywound mantel clock does not strike the correct hour, grasp the HOUR HAND ONLY and move it forward or backward to line up with the correct hour on the dial indicated by the number of times the hour strikes. Rotating this hand independently will not damage the clock. If the minute hand needs to be reset (to correct time), move the minute hand counterclockwise (backwards) as described in the “FOR ALL CLOCKS-SETTING TIME” section of these instructions.

CLOCK WILL NOT CHIME OR STRIKE

HAMMER

- Make sure that the selection lever is not in the “silent” position or halfway between two ARM chime melody positions?

- Make sure that all the packing material is removed from the movement area.

- Make sure that the clock is wound. CHIME

- Check hammer adjustment and correct chime tone as necessary.

or

5. Lift all hammers approximately one inch and then let them return to their resting position.

CHIMES HAVE THE INCORRECT TONE

DO NOT ADJUST CHIME HAMMERS, unless the chime tone is incorrect. Chime tone may be affected by the hammers resting on the chime rods or striking the rods off center. Although the hammers were set at the factory, it is possible for them to get out of adjustment. For most clocks, it will not be necessary to adjust chime hammers. There are different types of chimes (rods, coils MOON DIAL

and bells).

Chime hammer arms are made of brass and can be safely bent. If necessary, adjust hammers so that they do not interfere with each other while moving or striking the chime rods, chime coil or chime bell. This is accomplished by bending the hammer arms slightly in the middle so that each hammer rests approximately 1/8” from each rod or 1/8” from the coil or bell. (See figure 11). DO NOT bend the chime rods or chime coil. Chime volume cannot be adjusted.

CLOCK WILL NOT RUN

Although it is not recommended that you repair your own clock, you should check these items before contacting Howard Miller, your dealer, or an Authorized Service Center. Do not attempt any.

CLICK adjustment you do not feel confident in making.

1. Has all the packing material been removed from the movement area?

- Did you wind the clock?

- Is the clock level?

- Do the hands operate without interference? Do not let the hour hand hit the second hand. If the second hand is rubbing the dial, pull it out slightly. If the hour hand is rubbing against the back of the minute hand, the hour hand should be pushed closer to the dial (put your thumbnails on the center portion of the hour hand and push).

- Make sure the pendulum is hanging correctly in the pendulum guide.

DIFFICULTY TURNING THE MOON DIAL (if equipped)

As you face the clock, remove the back access panel. Look at the back side of the dial and locate the click spring. Put your finger at the tip of the click spring. Pull the click spring approximately 1/2” back away from the saw tooth moon dial and then release. (See figure 12). The click spring and dial should snap into proper alignment. If the click spring is in its proper location and you still feel resistance when trying to advance the moon dial, DO NOT FORCE IT. If the moon dial still cannot be easily advanced, this indicates that the gears that automatically advance the moon dial are engaged. To correct this, rotate the minute hand backward for three hours as described in the set-up operation.